Precision CNC Turning Services

Our Turning Services

MADE IN AMERICA

At Precision Ingenuity, we make it simple to bring your ideas to life with our CNC turning capabilities. From straightforward 2-axis turning to advanced Y-axis lathes with milling functionality, we deliver precise, high-quality parts tailored to your needs. Our machines can bar feed for efficient production, allowing us to hold tight tolerances across both small and large runs. Whether you need quick prototypes or scheduled production, you can count on us for accuracy, consistency, and reliability. Trusted by industries from food and firearms to defense and medical, we’re committed to providing the quality and service our customers depend on.

From simple 2-axis to Y-axis versatility, we’ve got turning covered.

Our Turning Capabilities

SERVICES

At Precision Ingenuity, our turning services are built for precision and efficiency. With bar feeding for continuous production, Y-axis milling for complex features, and dual-spindle lathes for true one-and-done machining, we deliver tight-tolerance parts that come off the machine burr-free and ready to use. Whether it’s a small prototype run or a large production order, we ensure every part meets your exact specifications—because in turning, precision isn’t optional, it’s the standard.

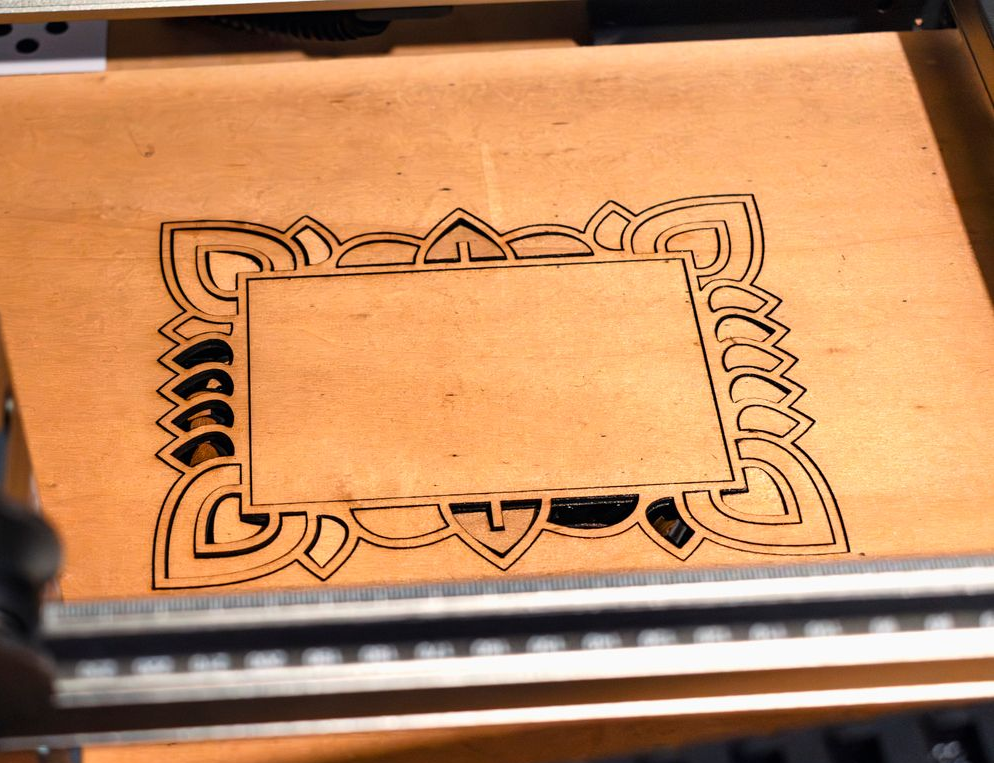

Personalized Gifts & Custom Products

Custom Detail, Built to Last

We create unique, personalized items with precision laser engraving, making every gift or product stand out with lasting detail.

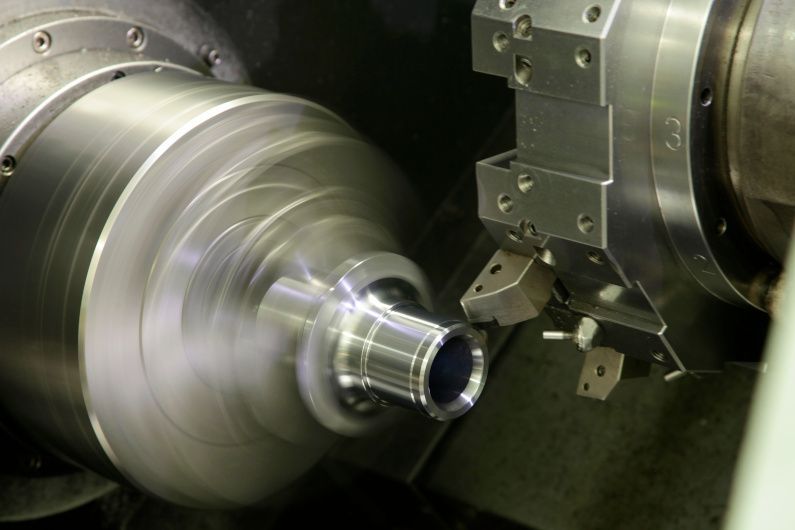

Simple Turning

Straightforward turning, precision every time.

Our 2-axis turning services provide a fast, reliable solution for producing round parts with tight tolerances. Ideal for shafts, pins, bushings, and other cylindrical components, this process ensures consistent quality across both small and large runs. With efficient setups and repeatable accuracy, 2-axis turning delivers precision without complexity.

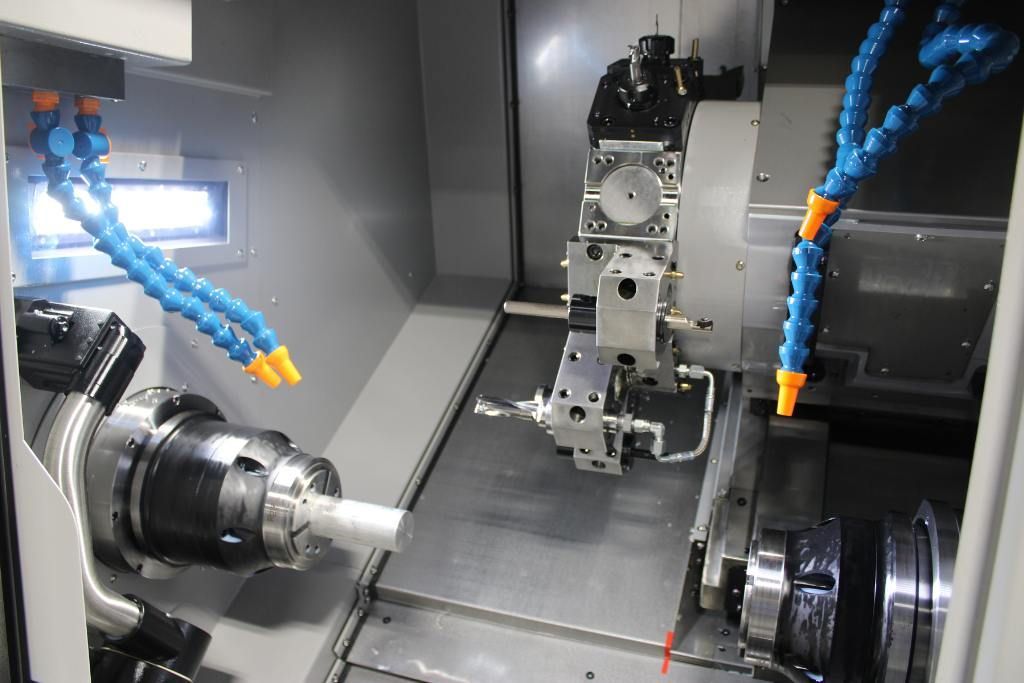

Mill-Turning

Milling and turning—done in one.

Mill-turning combines the power of CNC turning with the flexibility of milling in a single setup, making it ideal for complex parts with both round and prismatic features. With bar feeding, parts can be produced continuously for efficient small or large production runs. This “one-and-done” process reduces handling, shortens lead times, and ensures tight-tolerance, burr-free parts straight off the machine.

Contact Precision Ingenuity Today

We will get back to you as soon as possible.

Please try again later.