Post-Processing Services

The Value of Post-Processing

PROFESSIONAL SERVICES SINCE 2020

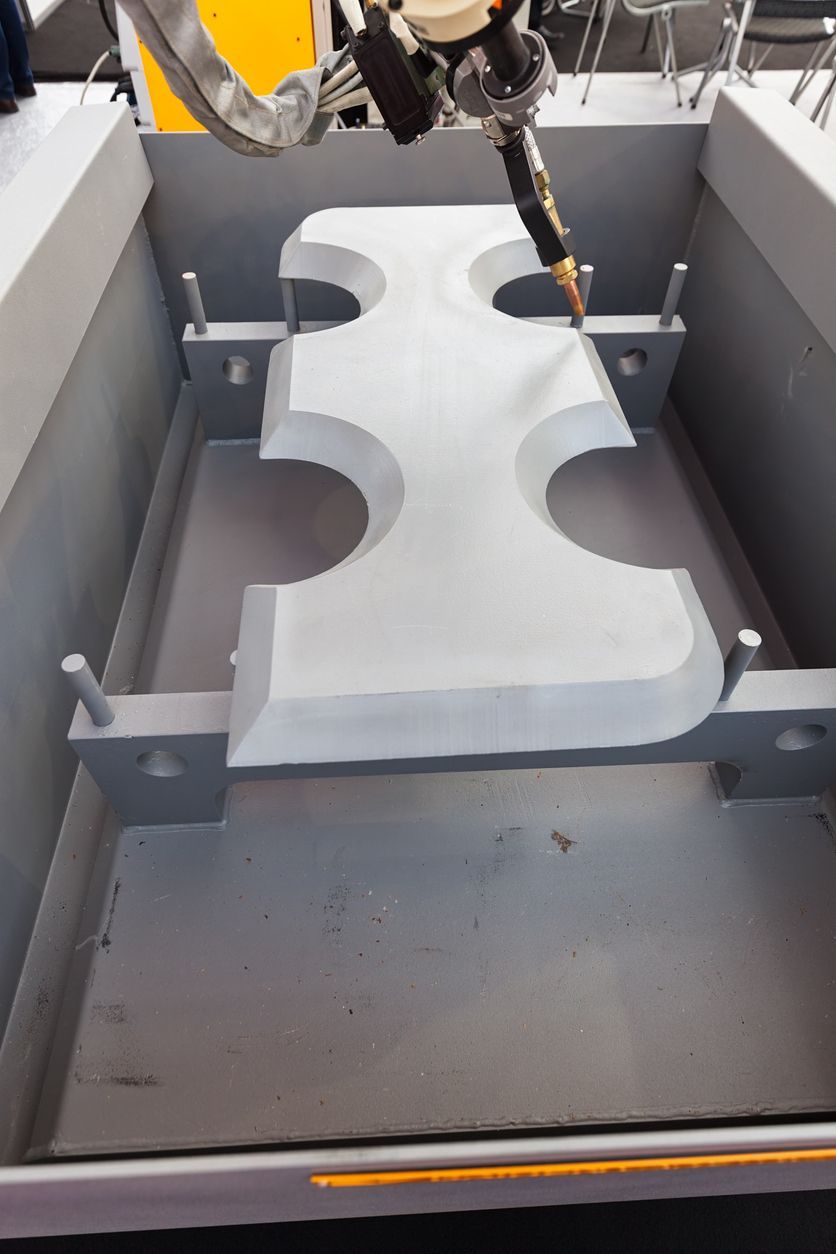

At Precision Ingenuity, we know that the job isn’t done when the machining stops. The final finish of a part is just as important as its precision and performance. That’s why we offer a variety of post-processing services to ensure your parts not only function flawlessly but also look and feel production-ready.

Our in-house capabilities include sand blasting, tumbling, laser engraving, and passivation, giving us the ability to smooth surfaces, remove imperfections, and apply detailed markings or protective treatments.

For projects requiring additional finishes, we partner with trusted external vendors to provide processes such as anodizing, Cerakote, and other specialty coatings. This means you can count on us to deliver a complete solution, from raw part to finished product—all managed under one roof.

Our Post-Processing Capabilities

SERVICES

At Precision Ingenuity, we believe the finishing touches make all the difference. Our post-processing capabilities ensure that every part leaving our shop not only meets tight tolerances but also has the surface quality, durability, and professional finish your project demands. From in-house treatments to specialized external coatings, we provide complete solutions to deliver parts that are production-ready and built to perform.

Sand Blasting & Tumbling

Smoother surfaces, stronger results.

Our sand blasting and tumbling services remove sharp edges, burrs, and surface imperfections, leaving parts with a clean, uniform finish. These processes improve both aesthetics and functionality, preparing components for further treatments or immediate use.

Passivation

Protecting performance through chemistry.

With passivation, we enhance the corrosion resistance of stainless steel parts by removing surface contaminants and restoring the natural protective oxide layer. This ensures long-term durability, especially for components in demanding environments.

Laser Engraving & Marking

Permanent precision, every time.

Our laser engraving and marking capabilities allow for highly detailed and permanent identification of parts. Whether it’s serial numbers, logos, or functional markings, we deliver crisp, professional results that withstand wear and use.

External Finishes & Coatings

Expanding durability and style through trusted partners.

We partner with trusted vendors to offer specialty finishes like anodizing and Cerakote. These coatings enhance corrosion resistance, durability, and appearance—delivering a professional finish tailored to your project’s needs.

Contact Precision Ingenuity Today

We will get back to you as soon as possible.

Please try again later.