Inspection

Inspection Services

MADE IN AMERICA

At Precision Ingenuity, quality is built into every step of our process. Our in-process inspections ensure each part is checked against strict tolerances before moving forward, catching even the smallest variances early to save time, reduce waste, and deliver consistent results.

Before shipping, every order also goes through a thorough final inspection. This guarantees each part meets customer requirements and industry standards, giving you full confidence in the finished product.

To support this, we maintain a temperature-controlled clean room for inspections. This controlled environment allows our team to use advanced measuring equipment with maximum accuracy.

Our Inspection Capabilities

SERVICES

At Precision Ingenuity, quality assurance is at the core of everything we do. Our inspection capabilities are designed to ensure that every part we produce meets the highest standards of accuracy, reliability, and performance. We take a meticulous approach to verifying precision at every stage. By combining advanced technology with strict quality protocols, we deliver consistent results you can trust for even the most demanding applications.

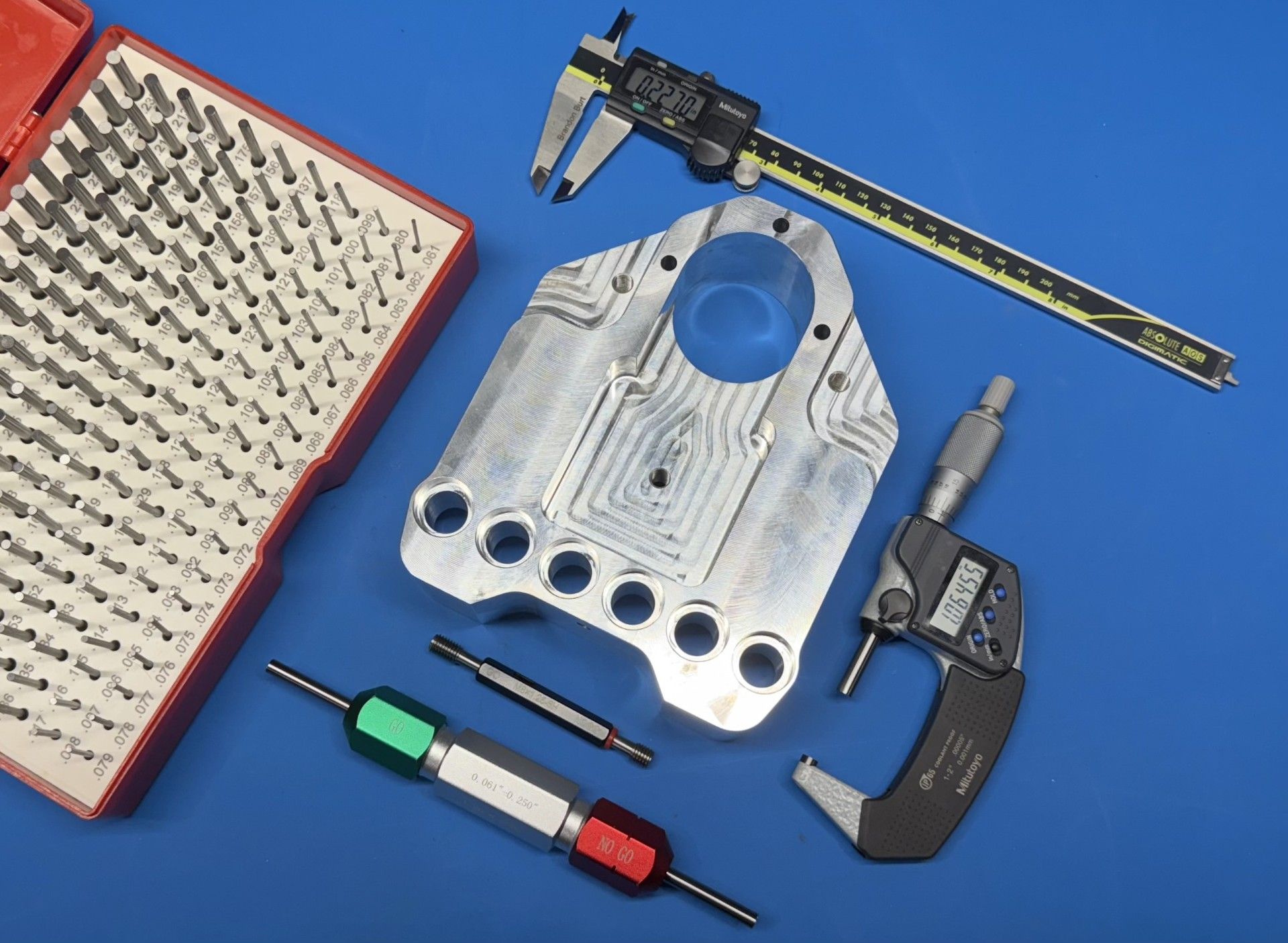

In-Process Checks

Precision verified at every stage.

Through rigorous in-process checks, our machinists verify critical dimensions and tolerances at multiple stages of production. This proactive approach ensures consistency, reduces scrap, and guarantees that every part leaving our shop is precise and dependable.

Temperature Controlled Environment

Accuracy starts with the right environment.

Our dedicated temperature-controlled clean room provides the ideal environment for precision inspection. Stocked with advanced measuring tools and calibrated equipment, this space allows our team to achieve the highest level of accuracy, free from environmental fluctuations that can affect results.

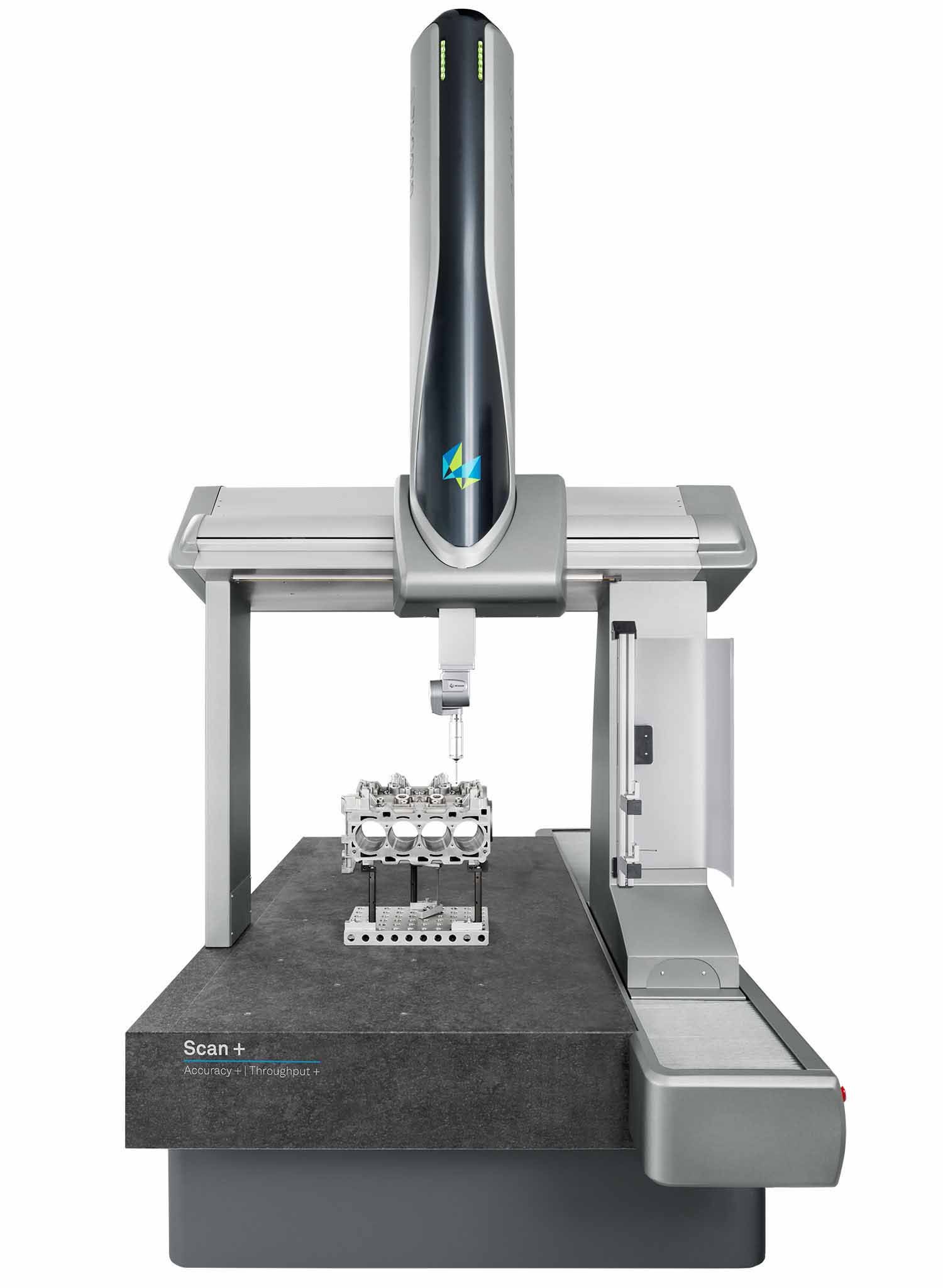

CMM (Coordinate Measuring Machine)

Advanced measurement for uncompromising quality.

For projects requiring ultra-high precision, we rely on our Coordinate Measuring Machine (CMM). This advanced technology provides detailed 3D measurements, confirming that even the most complex parts meet exact specifications. The CMM’s work area is 500mm (19.68") x 700mm (27.56") x 500mm (19.68"), giving us the capacity to inspect a wide range of part sizes with confidence and accuracy.

Contact Precision Ingenuity Today

We will get back to you as soon as possible.

Please try again later.